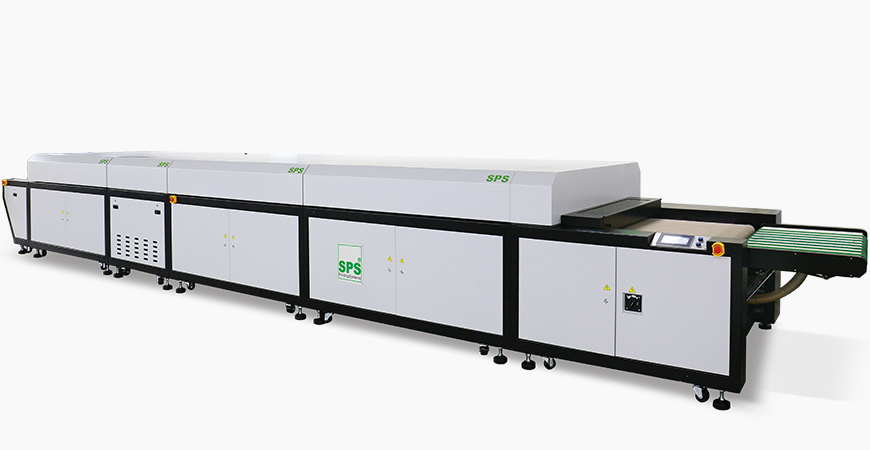

CBS 57

Jet Air + UV Combination Dryer

also called Jet Dryer, Forced Air Dryer, Tunnel Dryer, Tunnel Oven…

SPS CBS combination dryer, integrates hot jet air drying, UV radiation curing, cold jet air cooling multiple high efficiency functions is used to work with an SPS High Speed Fully Automatic Cylinder Screen Printing Machine, run synchronously linked, highlights German SPS’s advantage along with the lineage classic advantages (highest ever run speed, printing accuracy, operation convenience and comfort): full-line synchroline control link.

• Lined up after a Printing Press before a Stacker, as a process line.

• Working width 800mm, 31” (suitable for SPS 57 size equipment).

• Combines multiple drying modes (activated according to printed ink type): provides high volume hot jet air, dries solvent-based ink printed on sheet material, or provides UV (Ultra Violet) Radiation to cure UV-curable ink printed on sheet material; added air cooled with cold jet air (allows final sheet stacking stable after printing result).

• Speed is subject to ink drying speed (synced with SPS Screen Printing Machine).

• Provides Hot (under 90ºC) / Cold (room temperature) jet air to blow-dry solvent-based ink printed on sheet material, or provides UV (Ultra Violet) ray to cure UV-curable ink printed on sheet material, mode is selected according to ink type (cannot run both at same time)

• speed is subject to ink type and throughput of Press lined up ahead (SPS Dryer to sync speed with SPS Screen Printing Press).

• Modular design, configured by below sections as standard:

• Conveyor: high-strength ring-joint net belt + variable speed drive + tracking system, running through entire length, horizontally conveys sheets through below function sections, with pressurized airflow to stabilize sheets on conveyor surface.

• Infeed: not set with drying facility, just for ink printed on sheet to flow out before being dried(enhances gloss), and for surveillance or taking sheets out for inspection during run; the end connecting to Press is designed with fold-down vacuum belt system(fold-down provides passage for maintenance).

• Heating: 2 sections, main drying functional section, with high-pressure high-volume circulated hot jet air system, and enhanced heat-insulation mechanism.

• UV: main curing functional section, with 2 sets of 160w/cm high power UV ray emission lamp module and heat insulation/exhausting mechanisms.

• Cooling: with high-pressure high-volume room temperature jet air system, blow-cools sheet and ink on top of it(lessens impacts caused by remaining heat against sheet pile-up).

• Delivery: transfer sheets out toward Stacker lined up after.

• Graph/text display touch screen operator interface + function parameter setting/memory/call-out.

• Emergency stop + control safety system.

• Control may be linked with SPS Screen Printing Press ahead, Dryer speed to automatically sync Press speed.

• All top hoods may be hinge-lifted for inspection and maintenance.

OTHER OPTIONS:

• IR(Infra Red) ray module integrated inside Heating Sections: to boost temperature for higher efficiency

• Heating Section(whole section): to upgrade drying efficiency (productivity).

• IR ray top hood over infeed: to heat-soften printed ink, to speed up flow-out(mirror effect).

• UV ray top hood over infeed: for shape-fixing by pre-curing, or cracking effect owing to semi-curing.

• UV lamp module/Section(whole section): to upgrade curing efficiency.

• Chilled water heat exchanger system: to enhance cooling.

• Modular design, standard equipment:

- Conveyor: horizontally conveys sheets through function sections, with airflow systems to stabilize sheets.

- Infeed: control center, length for printed ink flow-out, sheet-flow surveillance, taking sheets out for inspection; infeed end may fold down (provides service access between printing machine ahead).

- Heating: 2 sections, thermal energy drying function sections, with high-volume hot jet air system, thermal-insulation mechanism.

- UV: UV energy curing function section, with 2 sets of high power UV lamp modules, thermal insulation/exhausting mechanisms.

- Cooling (ambient): with high-volume cold jet air system, forced-air cools sheet as well as ink on it.

- Delivery: transfers sheets out toward Stacker lined up after.

• PLC + touch screen operation interface + function parameter setting/memory/call-out, user-friendly for operation.

• Multiple automatic control systems, for convenience, safety, energy-saving.

• Control may be linked with SPS Screen Printing Machine ahead, automatically synced.

• All top hoods may be hinge-opened, for inspection and service.

- Conveyor: horizontally conveys sheets through function sections, with airflow systems to stabilize sheets.

- Infeed: control center, length for printed ink flow-out, sheet-flow surveillance, taking sheets out for inspection; infeed end may fold down (provides service access between printing machine ahead).

- Heating: 2 sections, thermal energy drying function sections, with high-volume hot jet air system, thermal-insulation mechanism.

- UV: UV energy curing function section, with 2 sets of high power UV lamp modules, thermal insulation/exhausting mechanisms.

- Cooling (ambient): with high-volume cold jet air system, forced-air cools sheet as well as ink on it.

- Delivery: transfers sheets out toward Stacker lined up after.

• Heating Section (add sections depending dry time and speed): to upgrade drying efficiency (productivity).

• UV top hood over infeed: for pre-curing / cracking or wrinkle effect.

• Heat exchanger system: to enhance cooling.