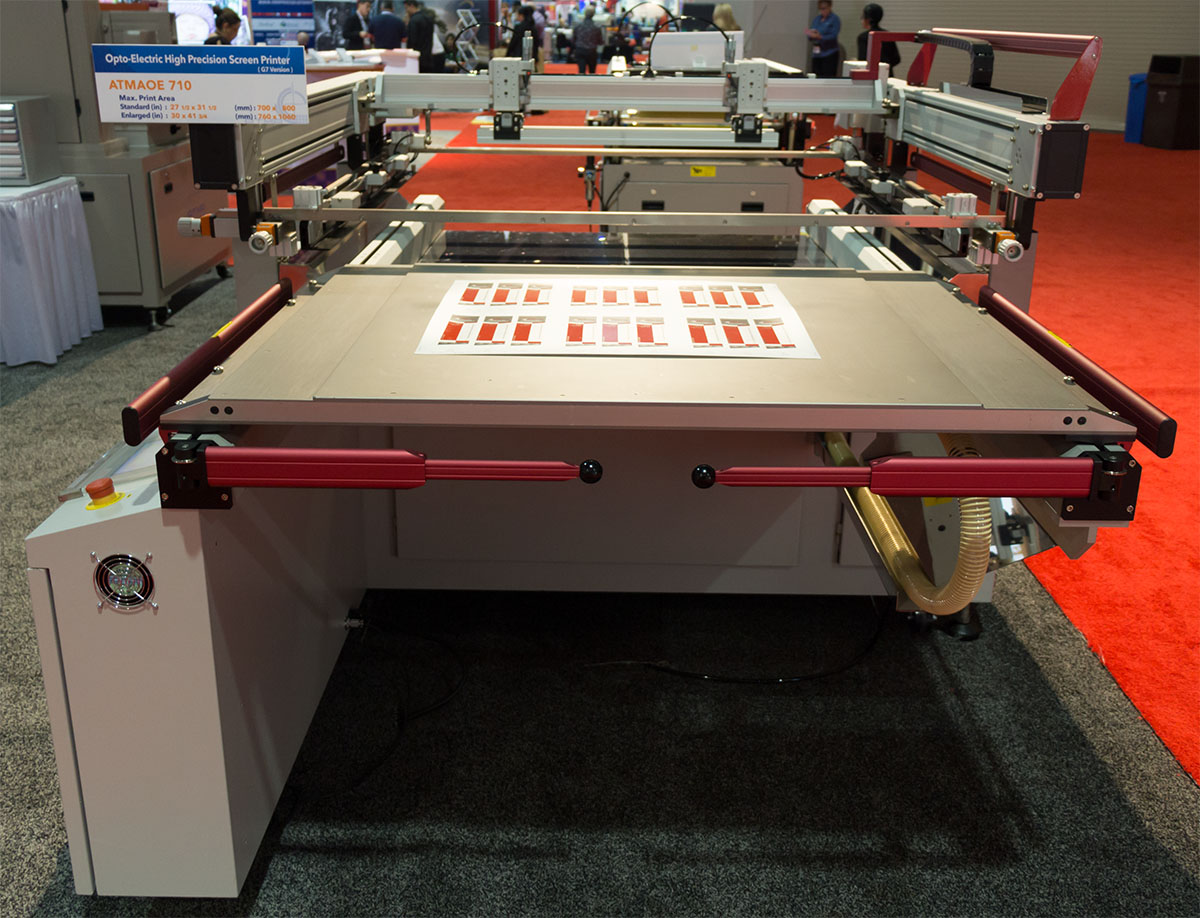

ATMAOE 56 / 67 / 710

Optoelectronic High Precision Screen Printer

(G7 version)

Suitable for High Precision Automatic Screen Printing. Applications include Membrane Switch/Overlays, Electroluminescent Panel, Light Guide Panel, Diffusion Panel, Touch Screen, Flexible Printed Circuit, Ball Grid Array, Flip-Chip Array, Cell Phone Cover Lens, Laptop Display Glass and much more.

Innovative Design

The latest G7 version four-post sliding table models are equipped with a new high rigidity structure design, top quality servo drives, 4-post locking of the print head, and ATMA's industry-leading precision guidance and positioning systems.

Stencil Structure

German motor + chain for four-post level positioning is controlled by digital touch screen. Equipped with leveling adjustment of screen frame at all four corners of the frame holder to allow fine adjustment to compensate for mesh tension and to position mesh parallel with the table surface. Printing and flood coater stroke is driven by servo motor for stable low and high speed control along with linear rails for smooth precise printing pressure to ensure absolutely even and uniform ink deposit. Preset servo peel-off controls when the peel-off position begins and stroke distance according to image size, with smooth lifting rate, and adjustable height between mesh and substrate. Includes no-peel flood function. Air supply shutoff with secure lock enables fast and safe screen installation/removal and micro-adjustment.

Electrical System

HMI digital color touch panel with 7" screen allows 100 preset functions and parameter settings to be saved and restored for repeat jobs. Once precise quality print output is achieved per job requirements the operator can save process data and records and then recall. This benefit is useful for different substrates and exacting print parameters maintaining high quality standard and facilitates faster changeovers and setup.

Safety

Safety guard stops machine immediately if normal operation fails or malfunctions. Error message and restart icon are shown on touchscreen. Safety features include safety bars, cycle start/interruption control on foot switch, emergency-stop button, automatic error diagnosis system, and power surge protection. Meets and exceeds all European and US safety requirements. FRL unit with pressure sensor will automatically interrupt printing if it detects insufficient air pressure. Front safety bar and bilateral side safety bars prevent movement of sliding table, screen frame, and print head if displaced. Screen cleaning button switch is located at rear side of guide rail profile for sliding table, locking machine movement to allow the operator to safely clean the rear side of the screen. Operator can lock out all switches from HMI to ensure that no manual switches can be activated at any time while cleaning underneath the screen.

Table Structure

German motor + swivel arm drives sliding table in/out along linear guide rail for accurate positioning within ± 0.05 mm. Linear Guide Rail is protected and supported by new high-rigidity aluminum extrusion profile with machined mounting surface for perfectly parallel movement of sliding table. Precision CNC machining for highest accuracy level, high strength aluminum alloyed table top maintains flatness better than +/- 0.10mm. Vacuum hole size 1.0 mm with a pitch of 20x20mm to ensure that substrate maintains even contact with table top throughout printing cycle, and ideal for thin films/substrates. Slotted table top on left and right end to enable lower off-contact for close tolerance printing accuracy.

Printing Structure

Fast and precise printing/flood coater stroke is driven by servo motor, which is directly connected the drive pulley for efficient and smooth operation. Touch-screen panel controls precise position, speed, and distance of squeegee/flood coater throughout print cycle. Squeegee/flood coater vertical movement is cylinder-driven with equalizing system for precise, smooth movement with uniform printing pressure to assure even ink deposit onto substrate. Equipped with precise dial gauge micro-adjustment structure for fine-tuning depth, skew-angle, and swivel-angle of squeegee and flood coater. Includes highly accurate air pressure adjustment valve and auto equalizing control of squeegee and flood coater.

Rigidity and Precision

Solid and light-weight structure combined with top-class transmission system enable fast operation, silent and stable sliding table, and precise positioning.

Options

CCD Surveillance System for screen registration, CCD Surveillance System for substrate registration, Gripper Take-off System with Up/Down Conveyor, Anti-drip System, Registration Pins, Cleaning Roller System, Static Eliminator, etc.

| Specification | ATMAOE 56 Metric Units | ATMAOE 56 Unit Conversions | ATMAOE 67 Metric Units | ATMAOE 67 Unit Conversions | ATMAOE 710 Metric Units | ATMAOE 710 Unit Conversions |

|---|---|---|---|---|---|---|

| Table Size (DxW) | 680mm x 700mm | 26¾" x 27½" | 800mm x 800mm | 31½" x 31½" | 950mm x 1250mm | 37⅜" x 49¼" |

| Table Height | 970mm+30mm | 38⅛"+1⅛" | 970mm+30mm | 38⅛"+1⅛" | 970mm+30mm | 38⅛"+1⅛" |

| Vacuum Area (Standard) | 420mm x 500mm | 16½" x 19⅝" | 600mm x 660mm | 23⅝" x 26" | 700mm x 800mm | 27½" x 31½" |

| Vacuum Area (Max) | 500mm x 600mm | 19⅝" x 23⅝" | 600mm x 740mm | 23⅝" x 29⅛" | 760mm 1060mm | 30" x 41¾" |

| Maximum Print Area (Standard) | 420mm x 500mm | 16½" x 19⅝" | 600mm x 660mm | 23⅝" x 26" | 700mm x 800mm | 27½" x 31½" |

| Maximum Print Area (Max) | 500mm x 600mm | 19⅝" x 23⅝" | 600mm x 750mm | 23⅝" x 29½" | 750mm x 1050mm | 29½" x 41⅜" |

| Minimum Print Area | 250mm x 250mm | 9⅞" x 9⅞" | 300mm x 300mm | 11¾" x 11¾" | 300mm x 300mm | 11¾" x 11¾" |

| Table Speed | 1000mm/sec | 39"/sec | 1150mm/sec | 45"/sec | 1150mm/sec | 45"/sec |

| Screen X/Y Adjustment | ±10/±10mm | ±⅜"/±⅜" | ±10/±10mm | ±⅜"/±⅜" | ±10/±10mm | ±⅜"/±⅜" |

| Substrate Thickness | 0.1mm - 30mm | 0.0039" - 1⅛" | 0.1mm - 30mm | 0.0039" - 1⅛" | 0.1mm - 30mm | 0.0039" - 1⅛" |

| Maximum O/D Frame Size | 950mm x 950mm | 37⅜" x 37⅜" | 1100mm x 1100mm | 43¼" x 43¼" | 1200mm x 1400mm | 47¼" x 55⅛" |

| Minimum O/D Frame Size | 800mm x 800mm | 31½" x 31½" | 900mm x 900mm | 35⅜" x 35⅜" | 1000mm x 1200mm | 39⅜" x 47¼" |

| Screen frame height | For the convenience of our customers, ATMA prepares all machines sold through RH Solutions to accept roller, diamond chase, and stretch and glue frames with heights 28mm - 52mm (1.1" - 2"). |

|||||

| Screen Height at Clean-up Lift Level | 285mm | 11¼" | 350mm | 13¾" | 350mm | 13¾" |

| Peel-off Stroke | 0-20mm | 0-¾" | 0-25mm | 0-1" | 0-30mm | 0-1⅛" |

| Print Pressure | 3 - 62 kg | 6.6 - 136 lb | 3 - 62 kg | 6.6 - 136 lb | 3 - 62 kg | 6.6 - 136 lb |

| Squeegee Inclination Angle | 20° ±5° | 20° ±5° | 20° ±5° | 20° ±5° | 20° ±5° | 20° ±5° |

| Print Head Speed | 20mm - 625mm/sec | ¾" - 24"/sec | 20mm - 625mm/sec | ¾" - 24"/sec | 20mm - 625mm/sec | ¾" - 24"/sec |

| Printing-head Skew Angle | ±5° | ±5° | ±5° | ±5° | ±3° | ±3° |

| Maximum Capacity (P/H non-stop full stroke) |

600 | 600 | 570 | 570 | 480 | 480 |

| Power Consumption (kW) | 2.93 kW | 2.93 kW | 3.25 kW | 3.25 kW | 3.35 kW | 3.35 kW |

| Power Source | 3∮, 220V, 50/60Hz | 3∮, 220V, 50/60Hz | 3∮, 220V, 50/60Hz | |||

| Air Pressure | 6.3-7.7 kg/cm² | 90 - 110psi | 6.3-7.7 kg/cm² | 90 - 110psi | 6.3-7.7 kg/cm² | 90 - 110psi |

| Air Consumption | 5 L/cycle | 1.38 Gal/cycle | 5 L/cycle | 1.38 Gal/cycle | 5.3 L/cycle | 1.47 Gal/cycle |

| Dimensions (WxDxH) | 150cm x 210cm x 145cm | 59" x 83" x 57" | 156cm x 240cm x 145cm | 62" x 95" x 57" | 200cm x 270cm x 145cm | 79" x 106" x 57" |

| Weight | 1000 kg | 2005 lbs | 1120 kg | 2470 lbs | 1155 kg | 2547 lbs |