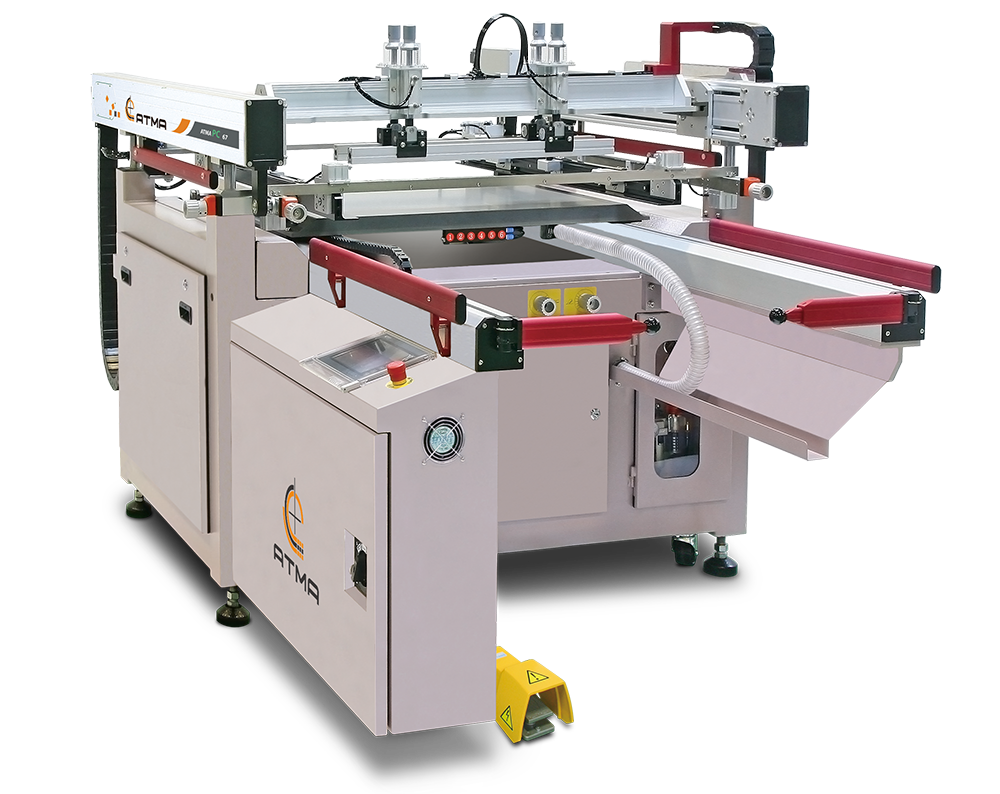

ATMAPC 67 Four-Post Screen Printer (new G6 version)

ATMAPC 67 Four-Post Screen Printer (new G6 version)

Suitable for precision screen printing on rigid and flexible non-deforming materials flat film / sheet / thin board, such as Mylar Overlay, Nameplate, Poster, Sticker, Decal, Sign, Flexible Circuit, etc.

Fast Setup

Convenient adjustment and setting functions raise productivity.

Safety Guard

Equipped with emergency stop switch, safe restoration, and automatic error diagnosis system.

Rigidity and Precision

Rigidity with light weight quality to harmonize with top class transmission system, fast operation, silent stable slide, precise positioning and energy savings.

Stencil Structure

- German motor + chain for four-post level positioning controlled by digital touch screen.

- Mechanism of screen vertical leveling adjustment is equipped at four corners of lateral left and right frame holder, enable to adjust screen leveling individually to compensate mesh tension and to secure mesh parallel with table surface.

- Screen frame holder is equipped with regi stration pin at rear side to achieve quick positioning at center location.

- Air locking is equipped for screen micro -adjustment and frame holder to obtain fast installing / removing screen as well as positioning. Check valve is attached to secure locking while air and power supply is terminated at abnormal condition.

- Preset servo peel-off controls when the peel-off position begins and stroke distance according to image size, smooth and stable lifting rate and height required between mesh and substrate. Includes no-peel flood function.

Table Structure

- German motor + swivel arm to drive sliding table in/outward leaded by Linear Guide Rail to achieve accurate positioning within ± 0.05 mm.

- Linear Guide Rail is protected and supported by new type high rigidity Aluminum extrusion profile, mounting surface was machined precisely to secure extreme parallel.

- Aluminum alloyed table top lamination achieves extreme strength and accurate even flatness (tolerance of flatness within ±0.10mm)

- Vacuum hole size ψ1.5mm with pitch 20x20mm to assure substrate flatness laid on table top.

Printing Structure

- Fast and precise printing stroke is driven by German gearbox with through shaft linked directly to drive pulley for efficient and smooth operation. Encoder controls precise traveling position, preset speed and distance of squeegee/flood coater through touch-screen panel.

- Linear Guide Rail is protected and supported by new type high rigidity Aluminum extrusion profile, the mounted surface is machined precisely for extreme parallel.

- Squeegee / flood coater up down is driven by cylinder with equalizing system, precise smooth leading expresses complete printing pressure onto substrate to assure even ink deposit.

- Equipped with adjustment structure for squeegee / flood coater to adjust depth / skew angle / swivel angle (micro adjustment of depth with precise dial gauge)

- Equipped precise air pressure adjustment valve and auto equalizing control for squeegee / flood coater.

Electrical System

- HMI digital color touch panel screen allows 100 preset functions and parameters to be saved and restored for repeat jobs. Once precise quality print output is achieved per job requirements the operator can save process data and records and then recall. This benefit is useful for different substrates and exacting print parameters maintaining high quality standard and facilitates faster changeovers and setup.

- Safety guard stops machine immediately if normal operation fails or malfunctions. Error message and restart icon are shown on touchscreen.

Safety Device

- FRL unit with switch for auto pressure detection, insufficient air pressure source may cause to stop machine running in order to secure all printing to get done in condition of sufficient air pressure.

- In case of front safety bar is not at home position, sliding table doesn’t come out to protect operator health and safety. (bilateral sides of machine and front of both sides are equipped with safety bar to protect operator safety.)

- Screen cleaning button switch is located at rear side of guide rail profile for sliding table, which is pressed to stop machine operation to protect operator cleaning screen at rear side. Operator can lock out all switches from HMI to ensure that no manual switches can be activated at any time while cleaning underneath the screen.

Options Available

- Dripless squeegee (swivel type): If dripless squeegee is applied, squeegee swings onto flood coater to prevent residual ink drip onto mesh to cause uneven ink spot.

- Anti-static bar : before table enters into printing section, static on substrate surface can be eliminated.

- Cleaning Roller (tack roller + adhesive type) : as table enters printing section, dusts or particles on substrate are removed to secureprinting quality.

- Gripper take-off : Additional gripper take-off and pneumatic registration pins can be added as an option. Please specify at time of order.

...

| Specification | Metric Units | Unit Conversions |

|---|---|---|

| Table size (WxD mm) | 800 x 1040 | 31½" x 40⅞" |

| Pneumatic pins | 6 pcs (square shaped) | 6 pcs (square shaped) |

| Vacuum area (WxD mm) | 740 x 600 | 29⅛" x 23⅝" |

| Max printing area (WxD mm) | 750 x 600 | 29½" x 23⅝" |

| Max frame O/D size (WxD mm) | 1100 x 1100 | 43¼" x 43¼" |

| Min frame O/D size (WxD mm) | 900 x 900 | 35⅜" x 35⅜" |

| Screen frame height | For the convenience of our customers, ATMA prepares all machines sold through RH Solutions to accept roller, diamond chase, and stretch and glue frames with heights 28mm - 52mm (1.1" - 2"). |

|

| Screen fine adjustment (mm) | X/Y = ±10 ; Z = ±2 | X/Y = ±⅜" ; Z = ±⅛" |

| Peel-off height (mm) | 25 | 1" |

| Peel-off type | Preset servo peel-off on touch panel | Preset servo peel-off on touch panel |

| Screen cleaning height (mm) | 350 | 13¾" |

| Substrate thickness (mm) | 0 - 30 ( 3/4 auto : 0 - 4) | 0 - 1⅛" ( 3/4 auto : 0 - ⅛") |

| Working table height (cm) | 97 + 3 | 38¼" + 1⅛" |

| Print head speed (mm) | 50 - 1250 /sec | 2" - 49 ¼" /sec |

| Max. capacity (pcs / hour) | 850 P/H (3/4 auto : 780 P/H) | 850 P/H (3/4 auto : 780 P/H) |

| Print head skew angle | ±50° | ±50° |

| Pneumatic type gripper | 4 pcs | 4 pcs |

| Conveyor speed | 360mm/sec | 14"/sec |

| Compressed air source | 6.3-7.7 kg/cm² | 90 - 110psi |

| Power source | 220/380V, 50/60 Hz | 220/380V, 50/60 Hz |

| Machine dimensions (cm) | 164 x 245 x 145 | 64 ⅝" x 96 ½" x 57 ⅛" |

| Control panel | Touch screen control panel | Touch screen control panel |